Electric Vehicle (EV) battery technology is transforming the automotive industry, with 2025 bringing major breakthroughs in performance, cost-efficiency, and sustainability. From lithium-ion dominance to solid-state innovations and sodium-ion alternatives, battery advancements are shaping the future of electric mobility.

The Current Landscape of EV Battery Technology

The demand for EVs has surged globally, driving manufacturers to create batteries that last longer, charge faster, and cost less. According to BloombergNEF, the average EV battery pack price dropped to around $115/kWh in late 2024, making electric cars more competitive with petrol-powered vehicles.

The rise of Lithium Iron Phosphate (LFP) technology has been crucial in reducing costs and improving safety. Leading producers like CATL and BYD dominate global supply, while new chemistries aim to diversify resources and reduce dependence on lithium, nickel, and cobalt.

Main Types of EV Batteries in 2025

1. Lithium-Ion Batteries (Dominant Choice)

- NMC (Nickel-Manganese-Cobalt): High energy density, suitable for long-range EVs.

- NCA (Nickel-Cobalt-Aluminium): Delivers strong performance and energy efficiency.

- LFP (Lithium-Iron-Phosphate): More affordable, safer, and longer-lasting — popular in budget and mid-range EVs.

2. Emerging Battery Chemistries

- Solid-State Batteries: Offer higher energy density, faster charging, and improved safety; large-scale production is still in development.

- Silicon-Dominant Anodes: Increase battery capacity but require engineering solutions to maintain durability.

- Sodium-Ion Batteries: Cost-effective and abundant; ideal for affordable EV models.

- Lithium-Titanate (LTO): Known for rapid charging and long life, mostly used in buses and fleets.

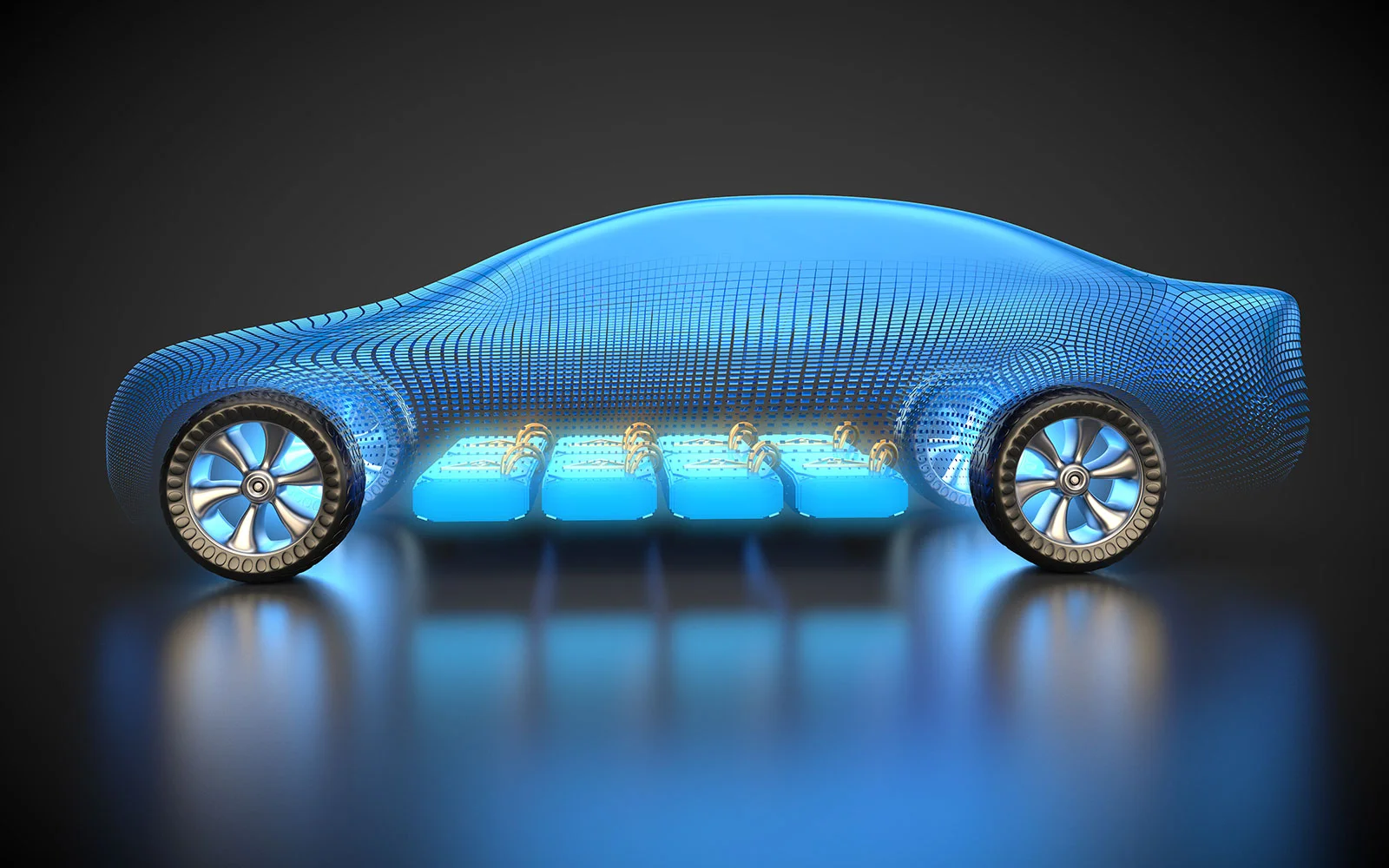

Battery Design & Cooling Systems

EV batteries come in cylindrical, prismatic, and pouch cell formats.

Thermal management systems, such as liquid cooling and advanced Battery Management Systems (BMS), are critical for maintaining performance, enabling fast charging, and extending battery life.

Fast Charging Innovations

Automakers are prioritizing high-C-rate cells to cut charging times dramatically. For example, CATL’s Shenxing battery can charge from 10–80% in under 15 minutes under optimal conditions. Cooling systems and ultra-fast DC chargers are key to making this possible.

Safety, Recycling, and Sustainability

LFP batteries are widely favored for their thermal stability, which minimizes fire risks. Recycling methods are advancing to recover lithium, nickel, and cobalt, while second-life applications — such as stationary energy storage — are gaining traction.

READ MORE: Heavy Duty Battery Lifter Carrier: Safe & Effortless Battery Handling

Leading Battery Manufacturers in 2025

- CATL: Leader in lithium-ion and sodium-ion technologies.

- BYD: Strong in LFP production with integrated EV manufacturing.

- QuantumScape & Solid Power: Innovators in solid-state technology.

- Tesla & Panasonic: Pioneers in cylindrical cell development and battery scaling.

The Road Ahead for EV Batteries

Expect 2025–2030 to bring:

- Wider adoption of sodium-ion batteries in affordable EVs.

- Gradual rollout of solid-state batteries in premium vehicles.

- Greater integration of silicon anodes for higher capacity.

- More investment in recycling and sustainable sourcing.

Conclusion:

EV car battery technology in 2025 is redefining the automotive landscape. With better chemistries, faster charging, and improved safety, electric vehicles are becoming more practical and affordable. This technological shift is not only boosting EV adoption but also paving the way for a cleaner, more sustainable future in transportation.